SINCR C500 series inverter application in constant pressure water supply

Abstract: Compared with the traditional water tanks and cisterns of water supply, constant pressure water supply with a large number of water saving, and do not cause water pollution. Taking a water supply plant with the frequency more than a trailer pump means to achieve constant pressure water supply, for example, introduces the SINCR C500 series inverter in the Water Supply System.

I. Introduction

The water supply automatic control system works, the equipment installed in the high pressure water supply medium sensitivity of sensors to detect changes in the water supply pipe network pressure when water changes constantly transmit a signal to change the frequency converter, a microcomputer calculates and determine the set after the pressure of comparison, changing the frequency issued instructions to the controller by changing the frequency to change the pump motor speed and the number of units enabled, automatically adjust the peak water use, to ensure that the water supply pipe network constant pressure to meet the needs of water users. C500 Water Supply diagram is as follows:

More than a drag supply schematics

II. the control requirements

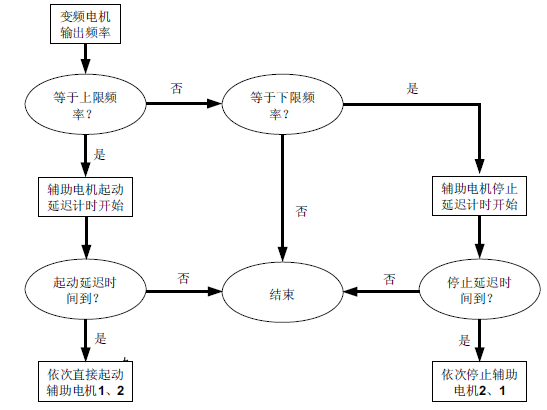

This article only SINCR inverter constant pressure water supply requires the use of the site as an example, shown in Figure 2, the specific control requirements are as follows:

Ø System Requirements 2set 4 kilowatts inverter control constant pressure water supply pump track, wherein each inverter can control up to three pumps, in which the inverter and control requirements including:

a. PID control to achieve a constant water pressure.

b. more than a drag control, reduce equipment investment, to achieve frequency conversion pump pump frequency and automatic switching.

c. G / P-in-one function, the flexibility to switch to different loads.

d. overload strong, stable operation.

e. compact and easy to install.

III. SINCR C500 Inverter Introduction

C500 inverter with DSP control system platform, using vector-based V / F control technology, and with a variety of protection, can be used in asynchronous motors, provide excellent driving performance. Products in duct design, hardware configuration, software functionality have greatly improved the customer ease of use and environmental adaptability.

Features:

◆ Frequency setting: Digital setting, analog set, pulse frequency setting, set the serial communication, multi-speed setting and simple PLC, PID settings, etc., and can achieve a combination of the mode setting switch

◆ accurate motor parameters self-learning, can accurately be rotating or stationary motor parameter self-learning, easy to debug, easy to operate, provide greater control accuracy and response speed

◆ vector of V / F control performance

◆ simple water feature, you can achieve a maximum of three trailers, Water Supply Control

◆ good voltage and current control, effectively reducing the number of inverter protection

◆ offers a variety of braking, quick stop

◆ high temperature over the whole point, is more suitable for high ambient temperatures in the textile industry of the occasion

◆ Speed tracking re-start function: to achieve the rotation of the motor without the impact of smooth start

◆ automatic voltage adjustment function: When the grid voltage changes, can automatically maintain a constant output voltage

◆ offers a variety of fault protection features: overcurrent, overvoltage, undervoltage, overtemperature, phase loss, overload protection function

IV. the system wiring and commissioning

The whole system is set up by a simple touch screen technology parameters, and real-time monitoring and recording the official website of the pressure situation, to facilitate the subsequent data analysis. Two inverters, each inverter can control three pumps achieve a drag three constant water supply function. system debugging

Debugging mainly include several technical points below:

First, determine the source of feedback, closed-loop PID control stroke.

Second, adjust the PID parameter values so that the pipe network pressure constant, small fluctuations.

Third, set up multi-pump switching parameters to achieve accurate switching hysteresis and does not appear abnormal.

Ø * Enter the basic parameters of the inverter, the way a given frequency, acceleration and deceleration time.

Ø * access to source voltage feedback signal, observed by parameter measurement range appropriate correction parameters set by P5.

Ø * Single pump operation constant voltage control, regulate PID parameters to quickly stabilize at the set value.

Ø * multi-pump switching function parameter set to meet process requirements.

Ø * long-term observation system stability.

Inverter parameter settings

Some of the key parameters of the inverter are shown in Table 1.

Table 1: C500 parameter settings Fact Sheet

Function Code | Function Description | Parameter Value | Function Code | Function Description | Parameter Value |

F0.00 | Control mode | 2 | F0.12 | Deceleration time | 20 |

F0.01 | Run command channel | 1 | F2.00 | Inverter type selection | 1 |

F0.02 | Frequency source selection | 6 | F9.00 | PID reference source selection | 0 |

F0.09 | Lower frequency | 20 | F9.02 | PID feedback source selection | 0 |

F0.11 | Acceleration time | 20 | | | |

The inverter has a short circuit, overload, overvoltage, phase loss, stall and other protection and fault output function, can effectively ensure the system safe and efficient operation.

V. Conclusion

The frequency control technology used in the field of liquid constant pressure for increased control on a dedicated control module that provides an optimized constant pressure water supply program, the use of this water supply special inverter assembly automatic control system, with less investment, high degree of automation, protection of functional, reliable, easy to operate, water-saving effect is remarkable, especially for water quality does not constitute a secondary pollution, with excellent cost performance.